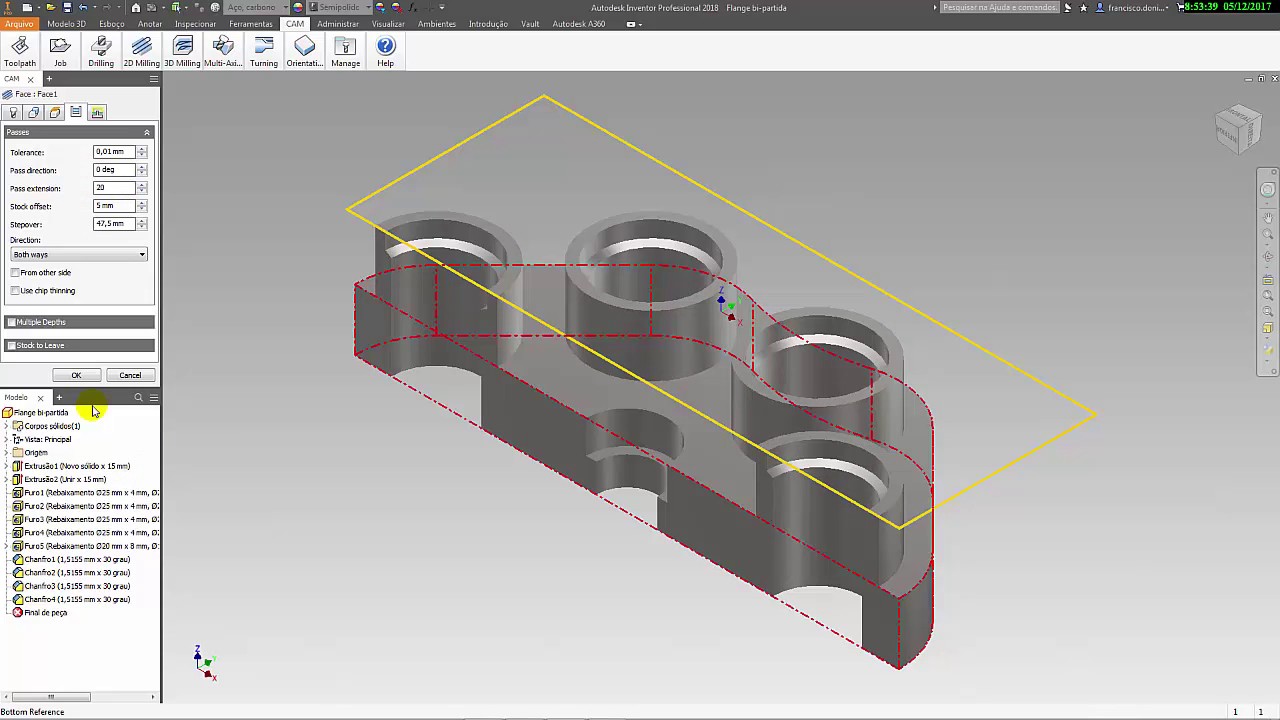

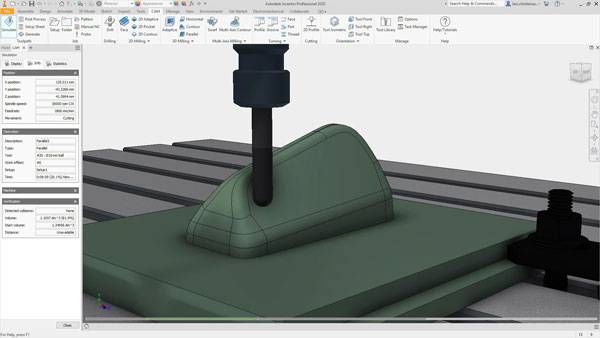

Our current workflow from Inventor to CAM is to manually lay out the flat pattern for each part and export as DXF to autocad where our CNC operator will open and import to Enroute to toolpath. We have a CAD team of three using inventor and a CNC machine running enroute. I work for a small joinery company that manufactures items for the retail / residential and exhibition industries. Topics, curriculum, and/or prerequisites may change depending on software version.I'm in need of some help with choosing CAM software to use with Inventor as It has become my role to update and make more efficient the way we operate in terms of CAD to CAM. It is recommended that users have prior experience with the Windows operating system, knowledge of 3D model creation/modification, and an understanding of the CNC milling process.Ĭourse description shown for Autodesk Inventor 2023.The Autodesk Inventor: Introduction to Solid Modeling course should be used to learn to create 3D models. Its focus is solely on generating 2D and 3D milling and drilling toolpaths once models are created. However, this course will not provide instructional content on how to create 3D models using the Inventor modeling tools. As an introductory course, Autodesk Inventor CAM: Introduction to 2D and 3D Milling does not assume prior knowledge of Autodesk Inventor CAM.Prerequisites for this Autodesk Inventor Training Course: Post process an Inventor CAM setup to output the CNC code required to machine a model.

Use the Simulation option to visualize toolpaths.Create 2D Milling, 3D Milling and Drilling toolpaths using the Inventor CAM interface.Set up machining operations using Inventor CAM.Locate, modify, and create tools in the Tool Library.

0 kommentar(er)

0 kommentar(er)